About

HighMag is a four-year European research project, funded by the EU’s Horizon Europe programme and backed by CINEA. It brings together 13 academic and industrial partners from across Europe, Switzerland and Israel to tackle one of the most urgent challenges in energy storage: developing sustainable alternatives to lithium-ion technology.

At the core of HighMag is a focus on Rechargeable Magnesium Batteries (RMBs) – a Generation 5 battery technology that harnesses magnesium’s natural abundance, lower cost, and enhanced safety. These attributes make RMBs a promising solution for next-generation mobility and other high-energy applications.

HighMag’s objective is to advance RMBs from Technology Readiness Level (TRL) 2 to TRL 4, through:

Developing innovative

cathode and anode

materials

Optimising essential

battery components

Applying advanced characterisation

techniques

Embedding Safe and Sustainable by Design (SSbD) principles across all research phases

Ensuring compatibility with existing lithium-ion production infrastructure to enable future industrial scalability

Through this collaborative effort, HighMag is committed to delivering a sustainable, high-performance battery solution that supports Europe’s transition to a greener and more resilient future.

Objectives

HighMag aims to offer a sustainable and low-cost alternative to Li-ion batteries

by advancing two Generation 5 rechargeable magnesium batteries with

enhanced energies: a magnesium-sulphur battery witha conversion cathode

and a magnesium metal battery with an insertion cathode.

Work will focus on:

Developing advanced materials and components (cathode, anode, electrolyte, separator) with improved compatibility and performance.

Progressing RMB technology from TRL 2 to TRL 4 using advanced characterisation and iterative development, with pilot-scale demonstrations.

Embedding Safe and Sustainable by Design (SSbD) principles, with strong attention to safety, sustainability, and recyclability.

Ensuring manufacturability and scalability, with compatibility to existing Li-ion infrastructure and guidance for future industrial uptake.

SPECIFIC OBJECTIVES

HighMag has defined eight clear specific objectives, each with measurable Key

Performance Indicators (KPIs), to guide its progress:

SO1

SO2

SO3

SO4

SO5

SO6

SO7

SO8

Expected Impact

The HighMag project is set to deliver significant impacts across environmental, societal,

and technological domains, bolstering Europe’s energy and sustainability goals.

Environmental Benefits

- Sustainable Materials: Utilising abundant Magnesium, Sulphur, and Manganese; significantly reducing reliance on Critical Raw Materials (CRMs) like Cobalt, Nickel, and Lithium.

- Cleaner Chemistry: Developing PFAS-free electrolytes and water-based electrode processing, replacing hazardous chemicals.

- Circular Economy: Embedding Safe and Sustainable by Design (SSbD) principles; focusing on design for recycling for easier material recovery.

Societal & Economic Gains

- Lower Battery Costs: Significant cost reduction at cell level due to inexpensive, abundant raw materials.

- Enhanced Safety: Achieving EUCAR Hazard level 3 for automotive applications, improving user safety.

- Strengthened EU Industry: Compatibility with existing Li-ion manufacturing infrastructure, easing transition and reducing capital expenditure for new production.

- Strategic Autonomy: Developing Generation 5 battery technology reduces reliance on external supply chains.

- Greener Mobility: Providing high-performance, sustainable power for electric vehicles and beyond.

Technological Advancements

- TRL Advancement: Progressing Mg-based, Generation 5 battery technology from TRL2 to TRL4

- High Performance: Targeting 500 Wh/kg specific energy and 600 Wh/L volumetric energy density.

- Fast Charging: Achieving 2-10C charge/discharge rates.

- Long Lifespan: Delivering 800+ cycles at 50% DoD or 400 cycles at > 80% DoD.

- Fundamental Insight: Gaining deep understanding of reaction mechanisms through advanced operando characterisation.

HighMag’s combined efforts are set to establish a credible pathway for the widespread adoption of magnesium batteries, contributing to a safer, more sustainable, and competitive energy landscape.

WORKPLAN

The HighMag project is systematically organised into eight interconnected Work Packages (WPs), each with clear objectives, ensuring a comprehensive journey from fundamental research to technology validation and impact delivery.

Project Management and Coordination

Oversees the overall execution of the project, ensuring scientific and technical milestones are met on time and within budget. Focus areas include quality control, intellectual property management, and communication with the European Commission.

Conversion & Insertion Cathode Materials

Designs innovative, scalable cathode materials for both Mg-S and Mg metal batteries. Focuses on sustainable synthesis, novel electrocatalysts, and high-throughput screening of high-voltage insertion materials..

Magnesium Electrolytes & Separators for High Performance

Creates PFAS-free electrolytes with enhanced performance and stability. Designs multifunctional separators compatible with both Mg-S and Mg-metal systems for improved safety and efficiency.

Magnesium-Based Powder Anodes & Protective Coatings

Develop high-efficiency magnesium-based anodes and apply protective coatings to reduce passivation and corrosion. Investigate powder-based anodes, explore alloy compositions, and test surface treatments to improve electrochemical performance and enable manufacturability at scale.

Advanced Characterisation

Delivers deep insights into material behavior using ex-situ and operando characterisation techniques. It aims to understand electrode structure, interface chemistry, and side reactions to inform material optimisation..

Technology Validation & Manufacturability

Validates battery chemistries through lab-scale cell testing, followed by the pilot-scale manufacturing of electrodes and the assembly of multi-layer pouch cells, tested for both performance and safety.

SSbD, TEA, Manufacturing & Recycling Assessment

Ensures technologies follow Safe and Sustainable by Design (SSbD) principles, are economically and socially viable, and can be recycled. Includes techno-economic analysis (TEA) and alignment with EU regulatory frameworks..

Communication, Dissemination and Exploitation of HighMag Results

Drives visibility and impact of HighMag through strategic stakeholder engagement, public outreach, and industry-focused dissemination. Supports commercialisation pathways and fosters collaboration within the European battery ecosystem..

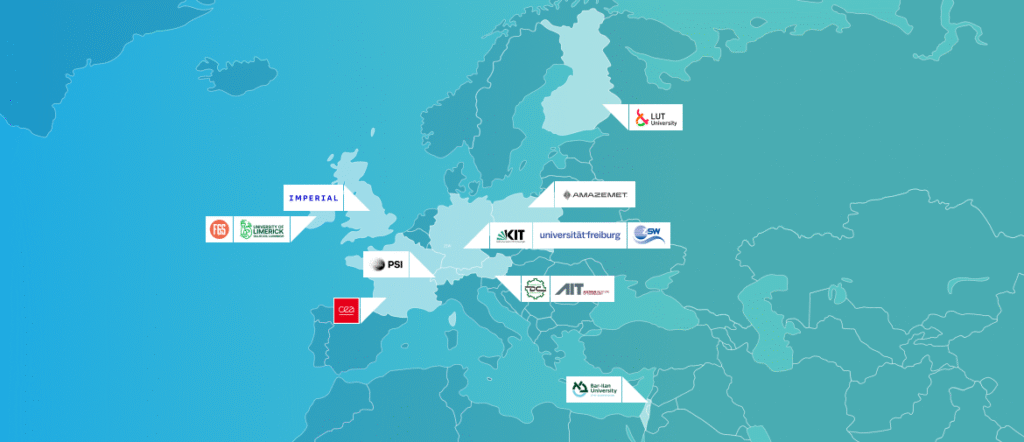

PARTNERS

HighMag is a collaborative initiative bringing together a distinguished consortium of thirteen academic institutions and industry partners from across Europe and Israel. This diverse group represents a wealth of expertise and innovation in battery technology.

Each partner contributes unique strengths, from fundamental scientific research and cutting-edge material development to advanced characterisation, industrial manufacturing know-how, and crucial insights into sustainability ahnd market exploitation.

This blend of academic rigour and industrial application ensures a comprehensive and effective approach to advancing rechargeable magnesium batteries. Working in unison, these partners are dedicated to achieving HighMag’s ambitious objectives and delivering a new generation of sustainable, high-performance battery solutions for the future.

Austrian Institute of Technology - (AIT)

The AIT Austrian Institute of Technology is Austria’s largest non-university research institute. With its seven Centers, AIT regards itself as a highly specialised research and development partner for industry. Its researchers focus on the key infrastructure issues of the future: Energy, Health & Bioresources, Digital Safety & Security, Vision, Automation & Control, Transport Technologies, Technology Experience and Innovation Systems & Policy. Throughout the whole of Austria – in particular at the main locations Vienna Giefinggasse, Seibersdorf, Wiener Neustadt, Ranshofen and Leoben – around 1,500 employees carry out research on the development of those tools, technologies and solutions that will keep Austria’s economy fit for the future in line with our motto “Tomorrow Today”.

At the AIT Center for Transport Technologies, around 200 experts are working on solutions for sustainable, safe, intelligent and thus future-proof mobility. The focus of the research and development work is on material-based lightweight design, on the electrification of the propulsion train and the storage of electrical energy, as well as on a resilient and safe transport infrastructure. This also includes environmentally compatible and intelligent production technologies for mobility components.

Project Coordinator, WP1 and wp6 Lead

University of Limerick (UL)

Based on the west coast of Ireland, the University of Limerick (UL) is a dynamic, research-led institution. With over 18,000 students and 2,000 staff, UL is recognised among the top 500 universities in the QS World University Rankings.

The university boasts a strong record in innovation and excellence across education, research, and scholarship, particularly within its Science and Engineering programmes. UL’s professional, career-focused approach and its engagement with industry ensure its offerings meet global standards. It has achieved prestigious 5-star QS rankings for areas such as graduate employability and innovation.

WP2 Lead

Commissariat A L Energie Atomique et aux Energies Alternatives (CEA)

Karlsruher Institut Fuer Technology (KIT)

In 2009, the University of Karlsruhe and the Research Centre Karlsruhe merged to form the Karlsruhe Institute of Technology (KIT). Building on a long shared tradition in research and education, KIT has grown into one of Europe’s largest single research institutions. It employs approximately 9,200 staff, hosts 5 departments and 13 faculties, and educates 25,100 students. Beyond its main Karlsruhe campuses, KIT operates additional locations in Ulm, Garmisch-Partenkirchen, and Dresden, with international offices in Brussels, Moscow, and Suzhou.

The Institute for Technology Assessment and Systems Analysis (ITAS), an interdisciplinary research institute within KIT, focuses on the technical, economic, environmental, and social aspects of emerging technologies. With over 130 scientists, ITAS investigates the impacts and potential wider effects of scientific and technological developments. It produces analytical knowledge and assessments, offering design options for decision-makers. Key areas of study include batteries, power-to-X technologies, and renewable energy. The team involved has extensive experience collaborating on systems analysis of energy storage, including participation in the POLIS Post Lithium Storage Cluster of Excellence.

WP3 lead

Albert-Ludwigs-Universitaet Freiburg (UFR)

Founded in 1457, the University of Freiburg is one of the oldest German universities and is now one of the nation’s leading research and teaching institutions. Dedicated to defining and pioneering new research areas, the university actively promotes international exchange and its central location in Europe and its proximity to Switzerland and France additionally supports its internationality. In regards to the Natural Sciences, it was ranked 6th in Europe and 2nd in Germany in a ranking of the European Commission according to their overall impact on scientific research.

Amazemet SP. Z O.O. (AMAZ)

AMAZEMET (founded in 2019) is a spin-off from Warsaw University of Technology, that has successfully transferred ultrasonic atomization, along with expertise in automated support removal, into state-of-the-art devices that are part of its portfolio. The focus of the company is to provide laboratory-scale units for the in-house manufacturing of powders with a tailored chemical composition that is suitable for various applications, including Additive Manufacturing.

The company also develops post-processing solutions such as affordable high-vacuum laboratory furnaces and devices for automated support removal and surface finishing. In line with the company’s origins and PhD students on its board, AMAZEMET maintains a strong connection with academic researchers by participating in collaborative research activities focused on developing new materials for AM, and partnering in projects, such as EIC Pathfinder, M-ERA.net, Horizon 2020 and ESA.

Bar Ilan University (BIU)

Established in 1955, Bar Ilan University (BIU) is one of Israel’s largest universities, marking five consecutive years as the Israeli university with the fastest-growing student population. BIU has achieved an international reputation for academic and research excellence, especially, but not limited to the fields of artificial intelligence, renewable energy, bio-medicine, brain sciences, cancer, cyber security, cognitive sciences, environment, medicine, archaeology and nanotechnology.

WP4 lead

Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW)

The work at the ZSW revolves around the development of eco-friendly technologies in photovoltaics and wind energy, batteries for electric vehicles and stationary applications, and also hydrogen – from generation by means of electrolysis right through to its use in fuel cells or further processing into synthetic energy sources. We also work on technical and economic concepts for their integration into energy systems. Prototypes and good designs will become products in the process of transferring the know-how to industry. We are also active in the political world and in the social arena in delivering analyses and recommendations for the successful implementation of the energy transition.

Danube Cell Manufacturing GmbH (DCM)

Danube Cell Manufacturing GmbH (currently founding) is an Austrian company specialised in battery cell design and manufacturing for special purpose applications.

DCM offers development and manufacturing services for pouch cells with bespoke performance and capacity. You bring the requirements, we produce the cells.

The core of our cell production is the close-to-requirements design and fabrication with maximum effort for sustainable and traceable battery cells. Our close development partner AIT Austrian Institute of Technology GmbH is a power house of new materials and process development – all of which can be directly transferred to DCMs cutting-edge cell fabrication.

Whether you need a few hundred prototype cells for demonstration of your new material technology, component validation or you have a production size that needs a few thousand cells specified for your needs – we have you covered and support you from the requirement phase to the finished and tested product.

Imperial College of Science Technology and Medicine (IMPERIAL)

Imperial College London (ICL) is a science-based university with an international reputation for excellence in teaching and research. The Resilience and Sustainability (R&S) group at ICL is at the forefront of developing assessment frameworks and methodologies for various sectors, assessing technological implementation and integration, aiming to reinforce public acceptance and social assessment of technologies, and thus support the transition from linear economy to a circular and sustainable economy. ICL will develop the eco-design framework for HighMag’s processes to ensure high sustainability standards, as well evaluating environmental, health, and safety aspects of tested materials and processes to ensure that the products are designed with safety in mind.

WP7 lead

Lappeenrannan–Lahden teknillinen yliopisto LUT (LUT)

LUT University seeks solutions to global issues with its expertise in technology, business, and social sciences. The university is a trailblazer in promoting the energy transition and the regenerative use of natural resources, and it helps build resilient communities, industry, and businesses through data, research, and education. Its campuses are in Lappeenranta and Lahti, Finland, but its impact is global.

F6S Network Ireland Limited (F6S)

F6S is a leading global founder and startup network that helps private and public sector entities around the world to promote, communicate and disseminate technical and research projects. F6S stands for F-ounder-S. Our mission is to help founders and startups grow to solve the world’s pressing social, economic, environmental, sustainability and innovation problems. In addition to F6S’ work with governmental entities, we also work with corporates, investors, research institutions, programs, universities and others in the global startup ecosystem. F6S tools deliver company growth through grants, funding, investment, pilot contracts, partnerships, jobs & talent recruitment, company services and more.

Role: Leader of WP10 (Communication, Dissemination and Exploitation)

WP8 lead

Paul Scherrer Institute (PSI)

With 2,300 employees, PSI is the largest research institute for natural sciences and engineering in Switzerland. It is the central location of Switzerland’s large research facilities. As part of the ETH Domain, PSI is a key pillar of the Swiss research landscape and conducts cutting-edge research in the fields of future technologies, energy and climate, health innovation and the fundamentals of nature.

WP5 lead